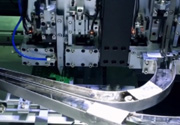

The tap-switch braid machine adopts the operation mode of the turret splicer to detect the power performance of the product and the appearance image of the pin. At the same time, the equipment contains the function of distinguishing poor quality products, automatic tape collection and automatic tape cutting, which improves the efficiency and strengthens the quality assurance of the product packaging. Applicable to electronic switches, plug-in terminals, connectors, hardware and other products.

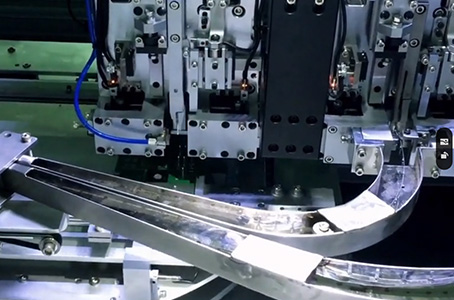

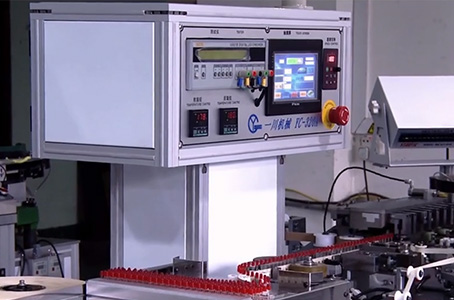

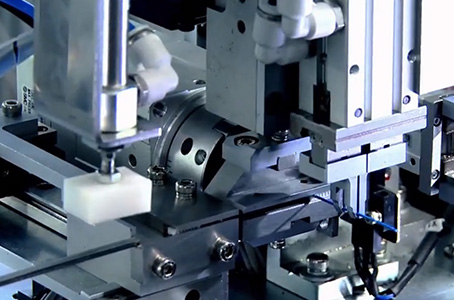

The mechanism action of the tap-switch braid machine is controlled by the advanced electronic and pneumatic components under the PLC program. The mechanical structure design is reasonable, the maintenance is simple, the precision error of the processed products and materials is ignored, and the stability of the machine itself is improved, with the characteristics of fast, stable and accurate. It makes up for the shortcomings of traditional processing methods, makes the original complicated manual operation mode realize automatic production, and makes the production efficiency be doubled and the product quality be strongly guaranteed. In the production and manufacturing industry of electronic products, product delivery is an indispensable process in the production process, the use of traditional manual operation method not only costs large investment, and the quality is not stable and effective control, under the general trend of modern industrial development, the switch braid machine using an automated way of production has become an inevitable.

The working principle of the switch braid machine: After the braid packaging machine and gas are connected, if it is hot packaging, let the knife rise to the appropriate temperature, and adjust the carrier belt and the air pressure of the air source. The SMD component is put into the load belt with manual or automatic feeding equipment, and the motor rotates the cover belt forming the load belt and the load belt are pulled to the packaging position, which is covered with the top and the load belt under, and the two heated blades press on the cover belt and the load belt, so that the cover belt seals the SMD component mouth on the load belt, so as to achieve the purpose of SMD component packaging. Then the receiving tray rolls up the encapsulated carrier tape.